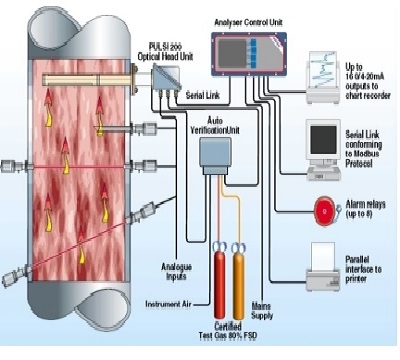

Continuous emission monitoring systems (CEMS) were historically used as a tool to monitor flue gas for oxygen, carbon monoxide and carbon dioxide to provide information for combustion control in industrial settings. They are currently used as a means to comply with air emission standards or state permitted emission standards. Facilities employ the use of CEMS to continuously collect, record and report the required emissions data.The standard CEM system consists of a sample probe, filter, sample line (umbilical), gas conditioning system, calibration gas system, and a series of gas analyzers which reаflect the parameters being monitored. Typical monitored emissions include: sulfur dioxide, nitrogen oxides, carbon monoxide, carbon dioxide, hydrogen chloride, airborne particulate matter, mercury, volatile organic compounds, and oxygen. CEM systems can also measure air flow, flue gas opacity and moisture. Optimum solutions to the measurement and monitoring of various pollutants like SO2,NOx, CO, CO2, NH3, HCI, HF, THC, Mercury, etc.

Analysis equipment and gauges